Leather strips - Leather laces - Leather straps

Leather strips as handles for a bicycle.

Contents

Leather strips - Leather laces - Leather straps

Leather laces and strips are used as jewellery or as driving belts. They can be cut in very different ways (see videos below). They can be cut round or into strips along a straight line. The round cutting gives a very long strip. Leather strips are therefore also sold by length. Cut with a simple knife the strips have an angular shape. With special machines, the square edges of the strips are rounded and are then round strips. Wide strips or laces are called straps. There is no clear definition for the transition.

Various leather laces.

Braided leather belt.

braided leather strips made of parchment.

Leather braided with leather straps over the seam in the Audi TT Roadster Moccasin.

Leather strips as sword handles.

Leather straps as a design element on the armrests of high-quality furniture.

Drive belts made of leather

Previously, drive belts were made of leather because leather possessed a range of properties that made it suitable for this application:

- Tensile Strength: Leather is naturally robust and has high tensile strength. It can withstand tensions and loads that occur when transferring power and torque from a driving element to a driven element.

- Flexibility: Leather is relatively flexible and pliable, allowing it to be wrapped around various rollers and pulleys. It can adapt to different shapes and sizes and smoothly glide over rollers to transmit rotational motion.

- Durability: Leather is known for its longevity. It is resistant to wear, abrasion, and tearing, making it a reliable choice for use as a drive belt.

- Slip Resistance: Leather has a natural roughness, providing good grip. This prevents the belt from slipping on the pulleys and ensures reliable power transmission.

- Vibration Damping: Leather also has the ability to absorb vibrations and shocks. This is particularly important for ensuring smooth and quiet operation of the drive system.

- Electrostatic Discharge: The low ability to accumulate static electricity was also a factor in using leather for drive belts. Compared to other materials such as plastics or synthetic fibers, leather has a natural ability to dissipate or minimize electrostatic charges.

Additionally, leather was widely available and relatively cost-effective. It could be easily cut into various shapes and sizes, tailored to meet the requirements of different drive systems.

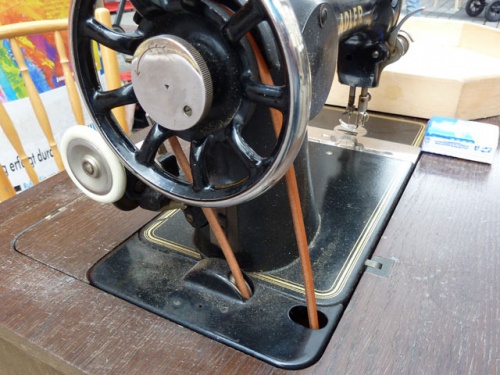

Round leather strips are used as driving belts.

Leather drive belt of a Harley Davidson.

Drive belt from a historic automobile.

Cutting leather strips and leather laces

Leather strips and laces can be cut with a variety of methods. They are cut round and long using different techniques and tools.

Round cut from the inside to the outside.

Round cut from the outside to the inside.

Cutting leather strips.

Additional information

- Leather bracelets

- Leather belt

- Leather watch strap

- Dog leash - Dog collar

- Bridle

- Leather whips

- Cords and straps made of animal tendons

a kotori web solution

a kotori web solution