Leather

Contents

- 1 History

- 2 What does leather consist of?

- 3 Why leather?

- 4 What materials can be called leather?

- 4.1 Basic requirements for the term Leather

- 4.2 The fibre structure

- 4.3 The layer thickness and the ratio of different layers

- 4.4 The proportion to other materials

- 4.5 Split leather

- 4.6 Artificial leather with leather fibres on the reverse

- 4.7 Patent leather

- 4.8 The labelling requirement for shoes

- 4.9 The marking of leather and fur by leather symbols or texts

- 5 Leather videos

- 6 Additional information

History

Leather has accompanied mankind since the beginning. At first, animals were hunted for food, and later bones, skin, and tendons were used for other purposes. The furs and hides of captured animals provided protection from the cold and humidity in the form of blankets, clothing, shoes or boots. Leather was also used for tent walls, kayak boat walls, thongs, belts or leather vessels. The ability to use leather made it possible to survive in the coldest regions of our planet and to live a more comfortable life overall.

Nowadays, most leather is made from farm animals. These are kept for meat production, milk production or for the production of wool.

In 2019, 90% of all people ate meat and despite the increasing number of people who eat meat-free, the world's need for meat is increasing due to increasing prosperity and increasing global population.

Cow leather, sheep leather, goatskin or pig leather are the most common. According to a survey in England in 2022, 50% of respondents believed that leather came from animals raised solely for leather production (which is incorrect) and only 24% of those surveyed knew that leather is a processed by-product of animal farming (meat, milk, wool).

The tanning process prevents the decay of animal skin.

Tanning is probably an accidental discovery. Initially, animal skins were fleshed, dried or smoked and rubbed with grease and oil to preserve them, to keep them soft and to make them water resistant.

At some point someone must have discovered that, when animal skin was soaked in water for a long time with plant residues, it absorbed the dissolved tannins from the residues and converted the skin to resistant leather. From this, tanners developed a sophisticated tanning process which made a long-lasting and durable end product from hides and skins. The oldest known tanning instruction was created around 700 BC.

At the end of the 19th century chrome tanning was discovered. This new tanning process shortened the production time enormously and was the start of the industrialization of leather production.

Today tanners offer endless types of leather with different leather surfaces and colours.

What does leather consist of?

Leather consists of intertwined collagen fibres (protein). Each collagen fibre consists of up to 2 million fibrils. The density of intertwining varies from species to species. But even within an animal skin, the density of intertwining differs significantly. A looser fibre structure is less resistant to tearing than a dense structure.

Leather in oblique section and cross section. At the top, the fibre intertwining is denser and more stable.

Depending on the type of leather, type of tanning and type of colouration, tanned leather comprises 45 to 75% hide substance, 8 to 45% tannins, 1 to 25% oils and/or fats, up to 3% dye and pigment colour and 8 to 15% moisture. The tannins prevent the decay of the hide substance and oils, fats and moisture make the leather supple.

The most common kind of tanning is chrome tanning. Leather clothing and leather shoes are almost exclusively chrome-tanned nowadays. Chrome III is harmless and occurs in many food sources. Today's leather goods are well-regulated and, apart from rare exceptions, free of toxins.

Genuine leather and artificial leather are different materials, where leather is the higher quality material. Even for experts, it is not easy to distinguish leather and artificial leather.

Why leather?

Leather is a noble, natural, durable and warm material, which is mainly used to make shoes, furniture, car interiors, clothing and leather bags. About 500,000 tons of leather is produced each year, equivalent to about 1.5 billion square metres.

Leather is a long-lasting product and can last for centuries if handled carefully. Nevertheless it is biodegradable (approx. 10-50 years). Alternative materials to leather have a significantly shorter durability. The basic components of the resulting waste are mostly synthetic materials that take 100 to 500 years to biodegrade. Some leathers will develop a beautiful patina over time, while alternative products will deteriorate over time. In addition, leather objects are much easier to repair than alternative materials in order to use them even longer.

It also has a technical advantage over alternative materials. Its fine fibres are so tightly intertwined that one gram of leather contains up to 300 m² of interior surface. As a result, leather has a high resistance to tearing, stretching and bending. It is also resistant to ageing and extreme temperatures. Leather hast the ability to store moisture up to 30% of its own weight while maintaining a dry feel. It can absorb moisture on the inside, then release it to the outside. Leather has an insulating effect. Imitation leather, or any other substitute, does not come close to displaying similar properties. In particular, for shoes and leather clothing, real leather has a clear advantage, offering unrivalled comfort with high durability. Leather is a malleable material. Whether as shoe, glove or clothing leather, leather adapts to the contours of the wearer over time. Another advantage of leather is its low flammability.

Leather is incredibly diverse. It can be produced from different animal species. There are many different types of leather. Suede, nubuck, buckskin, aniline, semi-aniline, pigmented leather, full grain, corrected grain, bycast, greased leather, waxed leather, oiled leather, fur and a lot more. The grain pattern of leather can be enhanced or flattened. It can also be carved with individual motifs or it can be embossed entirely. Buttery soft garment leather can be produced as well as hard and stiff leather soles and leather belts. Leather can be formed or perforated.

Leather from modern production is beautiful, durable and safe and, contrary to many prejudices, does not pollute the environment!

What materials can be called leather?

Leather can be manufactured and processed in a wide spectrum of varieties. It is mixed with other materials and frequently the question arises, whether using the description "Leather" or "Genuine Leather" conforms with local standards and laws, which differ from country to country. Sometimes there are even different rules for different uses of leather within a country. In Germany, for example, in upholstered furniture split leather must be specified in the description. It is not allowed to simply state "Leather". This rule does not apply to automotive leather. Many manufacturers of high-priced vehicles in Germany process split leather in car interiors without specifying it in the material description. In countries like France the rules are much stricter.

As the rules are different from country to country, this dictionary can only help to ask the right questions and to teach how to distinguish leather qualities. There are many varieties of good and bad leather. But anyone buying "genuine Leather", should always check, if the material is correctly described and if the leather quality is acceptable for the specified price prior to purchasing.

In particular, with online businesses or discounted offers "leather" is frequently declared incorrectly. It is difficult for the customers to find out if it's really "Genuine Leather".

Different countries have different norms, standards, regulations and terms to define leather and leather types. These are not laws. But norms and regulations help in case of disagreements and are cited by experts in legal disputes.

In Germany, for example, the following standards are important:

- RAL 060 A2: Defines the term "leather" and the differentiation from other materials.

- DIN EN 15987 (European standard): Leather - Terminology - Key definitions for the leather trade.

- DIN 68871: Defines the terms for leather for furniture upholstery.

- DIN EN 16223 (European standard): Leather - Requirements for the designation and description of leather in upholstery and automotive interior applications.

- Directive 94/11/EC (European standard): Directive of Euorpean Parliament and Counciel on the approximation of the laws, regulations and administrative provisions of the Member States relating to labelling of the materials used in the main components of footwear for sale to the consumer.

- ISO 15115: Leather - Vocabulary

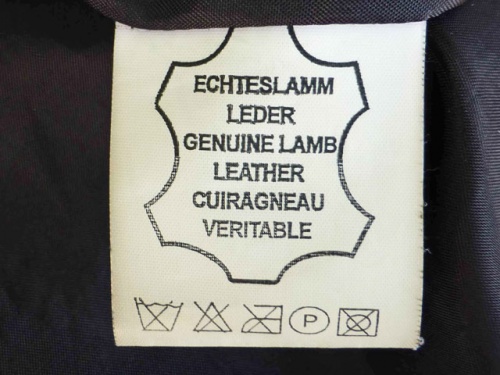

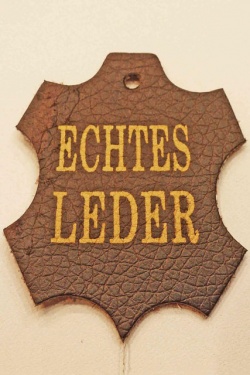

Symbol genuine leather.

Basic requirements for the term Leather

As each country has different declaration rules, we believe some basics should be taken into account in all countries to assure that the use of the word "leather" is not meaningless.

Different languages and countries have different terms used to describe leather and types of leather. Rules and laws should govern the use of terms and should make sure that such terms can only be used where leather is meant. In English language declarations like Aniline, Nubuck, Suede, Napa, Genuine Leather, Cow Hide, Sheepskin, Leather Jacket, Leather wallet etc. should describe the material "leather" as defined in the norms and regulations.

If a product is not leather, this information must be easy to find and clearly explained to the consumer. Lower case notes on the reverse and/or flowery declarations are not enough. The material declaration must be easy to understand to all and easy to find.

For materials which only look like leather, descriptions or names which might lead the customer to believe they are buying genuine leather should not be allowed. An exception in a lot of countries are the words describing imitation leather. But as long as consumers are familiar with words like Faux Leather, Imitation Leather, Synthetic Leather or Artificial Leather for describing imitation leather, these designations should be allowed.

Confusing name inventions like Koskin, Textile-Leather, Regenerated Leather, Vegan Leather, PU leather, Leatherette, Ultrasuede, Faux Leather, Pleather etc. should be forbidden. These names have previously been used for non-leather materials. Most customers thought they were buying Genuine Leather.

Depending on the country, the local language and tradition, descriptions like Faux Leather, Faux Fur might also be confusing for the consumer. Often such descriptions are in English, even if the national language is not.

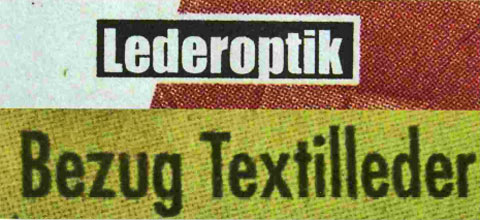

Descriptions like leather Look and leather-like should be understandable, but also depend on the local language and the way how consumers interpret such descriptions.

New materials based on sustainable components are on the market. These natural components, often from plants are combined with PU or PVC to be resistant enough. These materials are not leather, but named like cork leather, pineapple leather, mushroom leather, wine leather etc. This is not correct, as the materials are not leather.

Clear explanations should be allowed and deceiving the customers forbidden.

Declarations like "Leather-Look" plus "Textile Leather" are not allowed in Germany. Especially the use of "Textile Leather" is forbidden.

The fibre structure

The word "Leather" should only be allowed if the split or unsplit tanned skin of animals with its more or less intact original fibrous structure is described.

Materials which are produced from milled or shredded leather have to be clearly marked. A typical term for such material is bonded leather. This is misleading for consumers as it is not well known to all and the percentage of leather fibres is not clearly indicated. It has been suggested that the use of the term "Bonded Leather" should only be allowed for materials containing a minimum 50 % of leather fibres and to only allow clear descriptions like "Bonded Leather containing 60% leather fibres and 40% non-leather substances".

The layer thickness and the ratio of different layers

In a lot of countries, leather that has a surface coating or surface layer thicker than 0,15 mm, has to be declared as "Coated Leather" irrespective of the way the coating was applied. If the coating or surface layer exceeds one third of the total thickness of the product, it's not even allowed to be called "Coated Leather". In such cases, it`s not leather any more. This is also important when thin layers of leather are glued onto other materials.

- > 0,15 mm surface coating or leather: "Coated Leather"

- > 0,15 mm surface coating or leather and layer exceeds one third of the total thickness: Is not allowed to be called "Leather".

- Composite materials (leather watch straps, leather belts, leather mobile phone cases etc.) with less than 80% leather in the total thickness must be clearly declared to the consumer (e.g. outside leather, inside textile).

The proportion to other materials

The surfaces of leather objects relevant to their use must consist predominantly of genuine leather, or may otherwise not be so described. That is the case if the product is mainly made of synthetic leather. Basically, the relevant materials have to be declared unequivocally (for example "artificial leather bag with leather decoration").

A leather interior of a car must predominantly have leather on the major surfaces.

If the leather is permanently connected with another material (for example glued on a textile base), it can only be classed as a leather item, if leather represents 80% of the total thickness. Otherwise, external and internal materials must be declared separately.

Split leather

The declaration of split leather is different in almost every country and, in most cases, with a lot of contradictions. In Germany RAL 060 A2 allows split leather to be described as genuine leather. DIN EN 15987 only allows the term "split leather". "Leather" alone is not sufficient.

It is beyond dispute that split leather is not of the same quality as grain side split. Sometimes the flesh side split is coated with a finish and embossed or a layer of embossed and coloured polyurethane is glued to the surface to let it look like the more valuable grain side split. The end consumer cannot identify the quality. The leather is then like a low-grade wood veneered with exotic wood. The upper side is coated suede and the grain texture is created by embossing.

Inexpensive furniture is often manufactured with coated split leather or imitation leather on outside surfaces and the contact areas (backs, seats, armrests and armrest insides) are processed with grain leather. In some countries, split leather is even forbidden on contact surfaces (Germany RAL-GZ 430/4). If the outside surfaces are not of grain leather, the declaration could be, for example, "Leather sofa - back and sides split leather". Unfortunately, furniture buyers are very often not properly informed. Therefore, when buying furniture, one should always ask what materials it is really made from. Unfortunately, the declarations - especially when buying online - are very often wrong. Therefore, always get confirmation of the material description in the invoice!

Also the car manufacturers up to the higher price ranges are increasingly using coated split leather for the unloaded areas (door panels, headrests, steering wheels) without a clarifying declaration. The consumer will then acquire, in good faith, a quality full leather trim with the associated extra costs only to receive partially coated split leather. Consumers who want to make sure that they are not paying just for split leather, should ask and get confirmation in the purchase contract.

It would be much better for the consumers if all producers were forced to set out clearly when split leather is used. As the consumer cannot distinguish between the two different qualities, it would create transparency and allow the consumer to decide whether the price for the offered material is appropriate. It would also stop the industry from offering more and more split leather in unexpected areas. There is a loophole that should be closed in many countries. In the long run, it will help the reputation of leather both as a material and also as an industry, when customers are clearly informed and do not need to be suspicious.

Film coating with split leather. - Film coating with PU leather.

Video about the production of split leather and PU leather.

Artificial leather with leather fibres on the reverse

Some producers of furniture offer an artificial leather with leather fibres glued to the reverse. These materials are then advertised as "leather-like" and supported by numerous arguments. But this material does not have the benefits of leather and is forbidden to be sold as "leather". It`s just a marketing trick.

An extreme example of false declaration. Imitation leather with leather fibres glued to the reverse, but at first glance it looks like real leather.

Genuine leather or artificial leather? The difference from the expert's point of view.

Patent leather

Patent leather can be so termed, even if the surface layer is thicker than 0,15 mm. It cannot be declared as "Coated Leather". This exception is understandable, because consumers evaluate the product correctly. In patent leather, it is generally known that a thicker layer is applied.

The labelling requirement for shoes

In Europe, there is a material labelling requirement for shoes, but not for other leather goods. It would be desirable for the protection of the consumer if such a requirement was applied to other leather products.

The marking of leather and fur by leather symbols or texts

Some clients seek genuine leather or genuine fur while others refuse all kinds of animal materials. As customer information, there are different symbols and texts in order to characterize the offered material. Refer to the information about "genuine leather" .

Leather videos

Additional information

- Artificial leather with leather fibres on the reverse

- The material examination of leather mobile phone case

- The material examination of leather belts

a kotori web solution

a kotori web solution