Brain tanning

Contents

Brain tanning - Buckskin - Indian leather

The tanning of animal skins with animal brain mass is an almost forgotten method and is rarely practised today. Historically, brain tanning was mainly done by North American Indians who also used smoke as a way of preserving the skins. This leather was also called "Indian leather" and "buckskin".

This tanning process was also familiar to the Zulus in Africa, the Sami in Scandinavia and the different groups of people from Asia. The hides of all mammals are suitable for brain tanning. The larger the skin, the harder the work.

Advantages of brain tanning: The brain was always readily available after the animals were killed and tanning with brain is a very fast process. It only takes a few days. Also, the technical effort is low and it is easy to make the leather soft. This method involves 100% natural products, so there is no need for additional "chemistry".

But there are disadvantages. Brain tanning is high on manual labour and the process is not as easy, compared to alternative tanning methods. The skin layer of the hair side, as well as the fat and flesh remnants of the back, must be carefully and thoroughly removed so that the brain can fully penetrate the fibres. This is the only way to ensure the leather gets beautifully soft. The brain mass must be pressed into the fibre with considerable effort.

To ensure a long-lasting softness of the leather, it was traditionally stored in a special tent over wood smoke, which gave the skin a dark brown tone and also made it waterproof, thus achieving better protection. Without this process, the leather turns out to be whitish and water-sensitive.

Video about brain tanning

Visiting a tanning course with brain tanning.

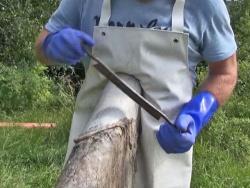

The fat and meat remnants must be removed. There is a clear separation between fat and meat remnants and the end product

It is not surprising to find insects stuck in the animal skin when the hair is scraped off.

Stretching the skin in the stretching and drying frame.

Dry-scraping must be done carefully from left to right and from top to bottom. The skin can be damaged if not done with care.

Any holes that exist in the leather need to be sewed up.

Brain tanning: Basically, the brain can be used for all animals. Usually, the brain mass of an animal is enough to make leather from its skin. It is available at the slaughterhouse or butcher, if one does not have the head of the animal. Brain is quickly perishable. Therefore, needs to be used immediately or must be frozen. Approximately 300 grams of brain mass is needed for a deer skin.

Variations of these methods are still used by do-it-yourself outdoorsmen to tan hides. The use of brains and the idea that each animal (except buffalo) has just enough brains for the tanning process have led to the saying "Every animal has just enough brain to preserve its own hide, dead or alive." Another saying: "Every animal has enough brain to preserve its own hide, except giraffe and teenager....".

Fresh brain when rubbing into a skin or in the stretching and drying frame.

Push in and squeeze it out again and repeat several times.

Softening: The leather has to be slightly moist for softening. Otherwise moisten the leather slightly with water. Thinner areas dry faster, so be careful not to dry out. To loosen the fibre, hold the leather with both hands and pull over a rounded and blunt edge. Alternatively, the leather can only be kneaded and stretched by hand. It is easier if several people pull the leather together to stretch it. You can pull the leather by rope loops or over lines and pull in opposite directions at both ends. This is hard work and needs experience.

In the beginning still funny, but hard work at the end. The skin is scraped with a piece of wood, pulled by a rope or a sharp wooden edge.

Smoking: By smoking, the Indians of North America prevented the leather from becoming hard as a result of moisture. Smoking waterproofs the surface. Due to the darker colour of the smoke, the leather does not look so dirty. This treatment allows the leather to be washed if needed.

Smoking the skins helps a lot.

Additional information

- Tanning leather

- Tannins

- Chrome tanning

- Vegetable tanning

- Synthetic tanning

- Tanning with fats and oils

- Buckskin

- Chamois leather

- Tawing with alum

- How to tan leather yourself?

Videos about the leather production

The leather production in a modern tannery.

The brain tanning process.

The leather production with tannins from the oak.

Chamois leather production in Germany.

The production of beaver skins.

| Process steps in the leather production |

|---|

| storage - soaking - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing (through colouring) and fatliquoring - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution