Difference between revisions of "Split leather"

| Line 31: | Line 31: | ||

<p align=center> | <p align=center> | ||

| − | <flashow>//www.youtube.com/v/ | + | <flashow>//www.youtube.com/v/eEcF6ez_iVM&fs=1&color1=0x660000&color2=0x550000&border=1|width=500|height=281,25</flashow> |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

Revision as of 18:08, 11 June 2019

Contents

- 1 What is split leather?

- 2 Video about the coating of split leather

- 3 Applications for split leather

- 4 The splitting of leather

- 5 Processed split leather

- 6 Coated split leather - Laminated split leather

- 7 Embossed split leather

- 8 Typical split leather damage

- 9 Additional information

- 10 Video about the leather production

What is split leather?

If a skin is divided into several layers over the entire surface, this process is called "splitting". Thicker leather, mostly cow leather, which is 5 to 10 millimetres thick, is split. The obtained layers are designated as grain split or top-grain split and flesh split. Sometimes, the leather is thick enough for a middle split. The split, separated from the grain split, is also called drop split. The drop-split leather is rough on both sides like the back of a leather.

When adjusting the splitting machine, the tanner must take into account that the thickness of the skin is higher at this stage due to the water content of the wet skin. The water content of a wet skin is three times heavier than the dry weight of leather. This water content also makes the leather thicker. The tanner has to consider this difference in thickness when adjusting the splitting machine so that the desired leather thickness is achieved once the leather is dry.

The hide is split. Above is the grain split and below the flesh split. Outside the tannery, only the flesh split is recognised as "split leather"

The grain split is considered more valuable. The fibre structure is substantially denser in the upper layer of the grain side and is thus tear-resistant. The grain split is referred to as smooth leather when tanned.

After leaving the tannery, the term "grain split" is no longer used. The leather dealer then uses terms such as "smooth leather", "aniline leather", "napa", depending on the leather type. The term "split" no longer appears in connection with the grain side. The drop split with the two rough sides is then no longer referred to as a "flesh split", but only as "split leather", "split" or "suede". In order to make the leathers more intelligible to the layman, this is an important separation of the choice of words in tanneries and in public. This makes it clear that the term "split" always refers to the less stable lower layer of the hide.

As the quality of a split leather is lower than the top grain leather, there are rules about the use of the terms. But the rules are different in almost every country. Some countries don`t allow to label split leather as "leather". Some allow it to be called leather, but only when further details make it clear that it's a split leather.

It is indisputable that a split leather does not have the same quality features as a top-grain leather. If a split leather is coated in such a way that it looks like a grain leather, the end user cannot recognise the quality. The leather is then like a veneered wood of lower quality. The upper layer with smooth leather optic is then not leather, but only a coating and the grain is created by an embossing process.

Therefore, labelling requirements are fair and acceptable from the end-user's viewpoint and split leather should be explicitly and clearly declared.

Video about the coating of split leather

Video about the production of plastic coated split leather.

Applications for split leather

Leather clothing

In the clothing sector pork split or goat suede are very common. Pig leather is generally somewhat stiffer and not as tear-resistant as a goat suede. Therefore, pig leather is mostly used for low-priced leather clothing.

Leather shoes

In the shoe sector, split leather is widely used for sneakers and sports shoes because of its breathability.

Suede is very common for shoes.

Furniture leather

In the lower price segment of leather furniture, better leather is processed for the contact surfaces (backs, seats, armrests) and, for the rest (outsides, back of the furniture), coated split or imitation leather is used. In the very low price segment, sometimes the complete furniture is covered with coated split. Usually such leather is only declared as "real leather" and similar terms. Such furniture then has a reduced life expectancy and, in some countries, if this happens within the warranty period, a successful claim for compensation can be made.

For this reason, you should always ask what materials have been processed. Unfortunately, the declarations are very often wrong, especially when buying online.

Car leather

Even vehicle manufacturers - luxury and lower end - increasingly use coated or embossed split leather on low contact areas (door linings, headrests) without the corresponding declaration. The buyer acquires in good faith a high-quality "leather interior" or "full leather trim" at a high surcharge.

Although no manufacturer provides information about processed split leather in their vehicles, companies specialising in split leather indicate that over 10 million steering wheels have been covered with split leather. Door linings, seat parts and other areas in the vehicle are also covered with embossed split leather.

Complete cow hides are over 5 square metres in size. The useable area of split leather for the automotive sector is 1.5 square metres from the butt area. This is the best part of the hide.

Split leather does not have the tear strength of a top grain leather. It is usually impossible to tear a top grain leather by hand, unlike split leather.

An indication of the material used would be desirable so that consumers are able to distinguish the split leather from the higher quality leather.

In principle, split leather is also not a bad leather, provided it is declared correctly and is produced for a long-lasting use. 99,9% of the customers believe that the smooth leather steering wheel or door trim is the grain side of the leather but, in reality, it is a coated split leather. Only a clear declaration would convey to the end customer in a comprehensible manner whether they had paid for a high-quality or cheap leather.

Therefore, always ask whether split leather was processed or higher-quality top grain leather was used, irrespective of which class or brand of vehicle you purchase. You can ask for it to be confirmed in the purchase contract.

The splitting of leather

Image 1: Cow leather is at split into at least two layers. - Image 2: Top grain leather with hair side.

The drop split is rough on both sides. After leaving the tannery it is called "suede" or "split".

Image 1: Splitting machine in the tannery. - Image 2: Thickness control measurement.

Processed split leather

There are many areas where split leather is the right choice. For shoes, clothing or bags, split leather is traditionally processed without any problem. It is usually the furniture sector, where split leather is sold with a smooth leather finish, which leads to disappointments among the customers.

Image 1: Split leather (suede) can be found in nearly every household in the shoe shelf as a sneaker. - Image 2: A suede leather chair from the 50s.

Coated split leather - Laminated split leather

In order to achieve an easy to clean and care surface and/or to let it look like a more valuable top grain leather, split leather is sometimes coated with a plastic film layer. Especially in the lower price segment, the customer is not informed that they don't have high-quality top grain leather, but inexpensive split leather with a film coating. Unfortunately, the complaint rates are very high for the cheap, coated split leather and the life expectancy is significantly shorter than for top grain leather.

The obligatory declaration is "coated leather" if the thickness of the coating is thicker than 0.15 millimetre.

Typical optics of coated split leather.

A new version of coated split leather from 2011 onwards is a split leather coated with a textile fabric. According to the manufacturer, the proportion is then 89% split leather and 11% other material of the coating. So far, this material has been offered under the names Rodeo, Pilot Leather and Tasan. The correct declaration for this material is "textile-coated split leather". This material is not to be offered as "genuine leather". It would be a false declaration and correct grounds for complaint in a lot of countries.

On the surface of suede is a textile layer of fabric. - Pilot Leather and Tasan.

Suede leather with a textile coating: Rodeo.

But there are more variants: split leather can also be laminated from the back with fabric for reasons of stability. From above it is coated and embossed.

Coated and embossed split leather with a textile lamination.

Embossed split leather

The term "embossed split leather" refers to split leather, which has been coated with a colour layer and embossed. These split leathers then look like a normal top grain leather. The quality is not so good, because the fibre structure of split leather is not very strong and not as strong as top grain leather. The tensile strength is much less.

Embossed split leather and corrected grain are not easy to distinguish.

Clearly embossed split leather. After removing the finish, suede becomes visible.

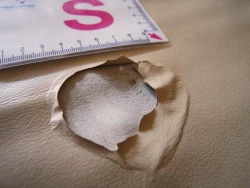

Typical split leather damage

Split leather is more susceptible to damage than top grain leather. Especially in the lower price segment, problems arise. The coating dissolves, the leather tears or becomes sticky in the area of skin and hair contact.

Cheap, coated split leathers often tend to detach from the film layer.

Dye transfer from leather and colour detachment.

Split leather tears in a very fibrous way and is also much more susceptible to cracks than top grain leather.

In the case of damaged top grain leather, the surface is smooth in the first phase of the wear of the colour coating.

Additional information

Video about the leather production

The leather production in a modern tannery.

| Process steps in the leather production |

|---|

| Storage - soaking - liming - fleshing - splitting - pickling - tanning - neutralising - withering - sorting - shaving - dyeing (through colouring) and fatliquoring - drying - finish - softening - final check |

| Tanning methods |

|---|

| Chrome tanning - Vegetable-tanned leather - Synthetic tanning - Tanning with fats and oils |

a kotori web solution

a kotori web solution