Difference between revisions of "Colour separation of leather"

| Line 34: | Line 34: | ||

<p align=center> | <p align=center> | ||

[[bild:Farbablösung-01.jpg|250px]] | [[bild:Farbablösung-01.jpg|250px]] | ||

| − | [[bild:Moebel Farbabloesung | + | [[bild:Moebel-Farbabloesung-03.jpg|250px]] |

</p> | </p> | ||

| + | <p align=center> | ||

| + | ''Delamination: Atypical colour detachment in furniture leather. No normal aging.''<br></p> | ||

| + | <p> </p> | ||

| + | |||

<p align=center> | <p align=center> | ||

[[bild:Moebel-Farbabloesung-02.jpg|250px]] | [[bild:Moebel-Farbabloesung-02.jpg|250px]] | ||

| − | [[bild:Moebel | + | [[bild:Moebel Farbabloesung 01.jpg|250px]] |

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''Atypical colour detachment in furniture leather. No normal aging.''<br></p> | + | ''Colour change: Atypical colour detachment in furniture leather. No normal aging.''<br></p> |

<p> </p> | <p> </p> | ||

Revision as of 18:38, 26 November 2016

Contents

- 1 Colour separation on Leather

- 1.1 Colour detachment in furniture leather

- 1.2 Colour separation at car leathers

- 1.3 Colour detachment in split leather, corrected grain or defective leathers

- 1.4 Colour detachment in PU leather

- 1.5 Colour abrasion and colour softening

- 1.6 Two-tone leather with colour abrasion

- 1.7 Rub off finish with colour abrasion

- 1.8 Colour detachment caused by deficient leather repairs

- 2 Tape Test to detect risks of colour separation

- 3 Additional information

Colour separation on Leather

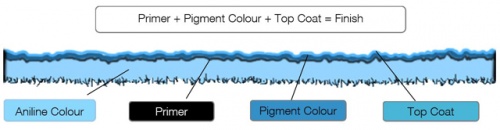

Illustration of leather dyeing.

Finished leather is applied with a layer of pigment based coat of paint on top in the tannery. Most times the colour layer is sprayed onto the leather. The colour layer can also be rolled or a coloured foil can be glued on top of the leather. With use, this colour layer wears off depending on the quality of the leather but it can also lead to unexpected colour separations.

Typical use related abrasion in car and furniture leathers.

Colour detachment in furniture leather

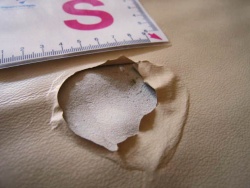

A regularly occurring problem, is the separation of colour on furniture leather. Initial signs of such colour separation can lead to an entire layer being pulled off.

There is a wide variety of reasons for such issues but the main cause is a quality problem of the leather colouring during leather production. Good leather is so well manufactured that colour separation cannot occur unexpectedly. Primer, colour and finish are sprayed rapidly one layer after the other so the fresh layers stick well together on each other and become inseparable. Sometimes the bonding to the lower layer is not good enough. This may be due to incompatible layers or long waiting time between the working steps. Then, the upper colour layer softens by contact with sweat on skin or hair grease and becomes unstable and sensitive and can rub off. The reason for this is not general use. It's a quality problem which shouldn’t occur. The phenomenon is also referred to as "delamination".

It happens that in the tannery the finish does not exactly have the color tone of the customer. Such leather, which cannot be sold elsewhere, is top finished again in the right tone. A "colour change" is done. If during the coloring process the existing and intact pigment finish is not sufficiently dissolved and / or sanded, a too little finish adhesion results which leads to the same color separation as in the case of delamination.

Delamination: Atypical colour detachment in furniture leather. No normal aging.

Colour change: Atypical colour detachment in furniture leather. No normal aging.

A shortcoming with testing standards is the lack of testing with skin fats. These naturally occurring fats dissolve the colour layer on the leather. Since this is not checked during testing stages, the leather is used and customers are blamed for misuse or incorrectly cleaning and maintaining their leather furniture. The industry is aware that the cause is a quality defect which does not ensure the practicality of the furniture, but this is not revealed by the tests. It is incomprehensible that there is no test for fats, as leather is traditionally cultivated with grease and oil based products, and each person has oily skin, greasy sweat and oily hair. The so-called "sweat test" only checks the pH value with a water based substance, but not the fat/oil sensitivity of the leather.

Typical colour separation in the contact area, within a few months of use.

Colour separation at car leathers

Car leather is usually thoroughly tested and very durable. Therefore, colour separation occurs rarely. But there is a phenomenon that happens in some cars where the colour layer peels off the rear seat by the window for no apparent reason.

Colour separation at the rear of the BMW 5 Series and Mercedes CLK from 2002.

Two more cases of the Mercedes CLK. Right W209 from year 2004. Left CLK of year 2003.

Colour detachment in split leather, corrected grain or defective leathers

Cheap leather has skin defects prior to tanning. These damages are filled with special filling products and colour layers or foil coatings hide this. To even out the surface, the |grain is then sanded down. Fibre looseness can break or partially dissolve the colour layer in later use.

Typical fractures in leather with poorer quality leather. The leather underneath the finish is unstable and cracks.

Typical colour separation on inexpensive split leather surfaces.

Typical film detachment in coated split leathers.

Colour detachment in PU leather

PU leather is plastic film coated split leather. Such leather is inexpensive and has variations in quality. Colour separation occurs frequently.

Typical cases of film separation in PU leather.

Colour abrasion and colour softening

Also, extremely soft finish can lead to stickiness and dissolve colour. This can be for various reasons.

- A tanners aim is to produce good quality soft and natural leather by following the exact process despite surface colouration. To achieve this, there should be an appropriate balance between softness and abrasion resistance. If the colour is too soft, it will become sticky and dissolves when exposed to heat and the forces of use. A typical example of this phenomenon was the Colour Concept of Volkswagen. Some vehicles had this problem. BMW had a leather with a chameleon-embossing in the Z4 model. Some customers found their seats be very sticky on hot summer days causing the colour layer to become sensitive. When trying to clean the leather, this partially dissolved finish rubbed off. Mercedes had a soft paint on the plastic parts of SLK. The paint was so soft that the colour could be taken off just by pushing with a fingernail. In forums, they called this phenomenon the "freckled" effect. Unfortunately, the parts usually had bright colours and the plastic underneath them was black. Specialised companies can re-dye those parts, but it is complicated and expensive. However, other vehicle manufacturers have painted plastics in door handles or even radio buttons where colour rubs down with time.

- Professional Leather repair companies colour older or damaged leather new again. Pigmented leather furniture gets damaged in hair and skin contact areas. The pigmentation softens and rubs of with the time. The rest of the furniture is still as good as new, but ugly grease marks deface the furniture. Specialised companies can degrease and re-dye those areas. If it is not sufficiently degreased during this process, the fats in the leather migrate back to the surface and the colour will need repairing again. It gets sticky and rubs of. Sometimes the grease stains have wandered for years through the leather, and only by a very thorough degreasing for several days, you can ensure that repairs are made permanent. The same applies to armrests and steering wheels in cars.

- Nowadays leather is coloured in a multilayer process. First, a primer is sprayed as a base, followed by leather colour and then the top coat. The Primer is a bonding agent which is set to be soft, so the leather also feels soft. If too much primer is applied in the manufacture or repair, the layer underneath the colour is extremely soft. When the leather heats up by sun or due to skin contact, the colour layer starts shifting towards the soft primer layer.

Too soft steering wheel colour. - BMW chameleon leather with pressure points of trousers rivets.

The SLK from Mercedes with "freckles effect".

Softened leather colour in the head area. - Specialised leather repair companies only are able to fix this.

Two-tone leather with colour abrasion

Antique leather or leather with a two-colour effect are similar produced. Mostly a darker and transparent colour layer is sprayed on a light covering colour. This gives the leather a colour depth. It can happen that the upper, semi-transparent patina colour wears off from the underlying main colour. This can have several causes. Sometimes the upper colour is too soft or too sensitive to water and grease (skin and hair contact areas). On Chesterfield furniture, that patina is accepted as that is an intentional ageing effect, but with modern furniture, it is considered a damage.

Often this phenomenon gets visible when cleaning the leather. The softened patina colour comes off during the cleaning process. In most cases, the manufacturer of the cleaner is suspected. The test is very simple.

Do a test with a damp cloth moistened with water. If the colour dissolves in the hair or skin contact areas by water, the cleaner is not the cause. In the unloaded area, the phenomenon can often not be reproduced because the colour has not been weakened or softened by the skin or hair contact. If a cloth moistened with water does not remove colour, the cleaner could be too strong. A too long moistening or excessive rubbing can soften or dissolve a leather colour too.

Typical abrasion of the patina colour by friction or softening in the contact areas.

Rub off finish with colour abrasion

Leather with a rub off finish is leather were a darker patina colour is wiped onto a lighter pigment layer. This rubs off over time and gives the leather its characteristic appearance. As long as the abrasion does not take place too fast or too much, it is a desired effect.

Typical abrasion of the patina colour, which is usually a desirable effect.

Colour detachment caused by deficient leather repairs

Damaged leather can be recoloured by specialised companies. Nevertheless, it can happen that the work is carried out incorrectly and the new colour layer also starts peeling. The detachment behavior is then the same as in the colour changing process in the tannery.

Reasons for colour detachments caused by improper repairs:

- Insufficient degreasing of sweat soaked contact areas of skin or hair.

- Shoes and boots treated intensively with silicone, oil and fat containing shoe care products are difficult to clean good enough before a colouration. These products then act like release agents.

- Some leather have anti soling additives in the top coat. If these are not properly removed before colouration, they may have the effect of release agents.

Experienced leather repair professionals know these problems and how the leather should be checked before any repair work. Most experts check by wiping with their hand over the surfaces to find out which leather could be problematic. Problematic leather has a greasy or slippery grip.

detachment of the top coat after improper cleaning before correcting the gloss level. - Detachment of the leather colour on shoes after improper degreasing before applying a new colour.

Tape Test to detect risks of colour separation

Sometimes colour layers or foil coatings get damaged and the layer can start peeling. To test this sensitivity, stick a masking tape to the leather and remove it straightaway. If the paint sticks to the masking tape, a quality problem could be an issue. If nothing sticks to the masking tape, the colouring is appropriate, even if the film or coating could be peeled using fingernails.

Important: In such cases, do not peel off the layer. First ask a leather repair specialist for advice before increasing the damage unnecessarily.

Peeling the layer enlarges the damage. - The tape test shows that something is wrong.

The tape test is also used by leather repair companies when testing if the surface is well prepared for a colour repair. If the masking tape doesn`t stick well to the surface, there is still something separating on the surface which will also reduce the adhesion of repair and colouring products. In most cases, such leather feels slippery or greasy. Such leather is not sufficiently degreased, not silicone-free, or otherwise coated with separating components.

Dye transfer from leather and colour separations of leather.

Additional information

a kotori web solution

a kotori web solution