Difference between revisions of "Aniline leather, refined"

m |

|||

| Line 10: | Line 10: | ||

==The gap between [[aniline leather]] and [[Semi-aniline|semi aniline leather]]== | ==The gap between [[aniline leather]] and [[Semi-aniline|semi aniline leather]]== | ||

| − | Pure [[aniline leather]] must not have a [[finish|pigmented surface]] of any kind, not even a minimal one, according to the definition of this [[Types of leather|type of leather]]. Therefore, aniline leather is susceptible to stains. As soon as any pigmentation is applied, | + | The lack of a defining standard between pure aniline leather and semi-aniline leather has led to a certain amount of confusion. Pure [[aniline leather]] must not have a [[finish|pigmented surface]] of any kind, not even a minimal one, according to the definition of this [[Types of leather|type of leather]]. Therefore, aniline leather is susceptible to stains. As soon as any pigmentation is applied, it is no longer classed as aniline leather. If the leather is only minimally pigmented so that it remains as natural as possible, the leather does not meet the minimum requirements for the leather type [[Semi-aniline|semi-aniline leather]] either. |

| Line 20: | Line 20: | ||

<p> </p> | <p> </p> | ||

| − | This conflict occurs mostly in [[leather furniture|upholstery leathers]]. | + | This conflict occurs mostly in [[leather furniture|upholstery leathers]]. Understandably, the leather furniture manufacturers want the best leather quality ([[aniline leather]]). But, at the same time, they want the aniline leather not to [[Colour fastness - Light fastness of leather|fade]], not to have [[natural markings on leather]] and as few colour deviations as possible and not be [[Porous leather|susceptible to stains]]. |

| Line 33: | Line 33: | ||

<p> </p> | <p> </p> | ||

| − | To solve this dilemma, some [[tannery|tanneries]] have applied thin [[finish|layers of pigment]] onto the leather. This was intended to be as close as possible to [[aniline leather]], while applying a light protection in order to meet the legitimate wishes of the furniture trade and the end users. If, during investigations, pigments were found on the surface the tannery would be accused of failing to sell high quality aniline leather. | + | To solve this dilemma, some [[tannery|tanneries]] have applied thin [[finish|layers of pigment]] onto the leather. This was intended to be as close as possible to [[aniline leather]], while applying a light protection in order to meet the legitimate wishes of the furniture trade and the end users. If, during investigations, pigments were found on the surface the tannery would be accused of failing to sell high quality aniline leather. Then, if it was tested for [[Semi-aniline|semi aniline leather]], it failed to meet the minimum requirements for [[Colour fastness - Light fastness of leather|light fastness]] or [[leather quality|friction resistance]]. |

| − | This regulatory gap gave the impression that the [[tannery]] had produced a deficient leather. But a leather that falls between [[aniline leather]] and [[Semi-aniline|semi aniline leather]] is of excellent [[leather quality|quality]]. It is [[finish|coated]] as little as possible to preserve the naturalness. | + | This regulatory gap gave the impression that the [[tannery]] had produced a deficient leather. But a leather that falls between [[aniline leather]] and [[Semi-aniline|semi aniline leather]] is actually of excellent [[leather quality|quality]]. It is [[finish|coated]] as little as possible to preserve the naturalness. Although this offers minimum protection, it ensures that this type of leather will not fade so easily and be less stain sensitive than completely [[Porous leather|porous]] aniline leather. |

| − | + | It's of little advantage to the consumer that pure aniline leather, which falls within the highest price bracket, [[Colour fastness - Light fastness of leather|fades]] over time and that normal stains are difficult to remove. Thus, slightly pigmented leather between aniline and semi-aniline is a much better option for leather manufacturers, leather traders, furniture manufacturers and the end customers. | |

==Aniline leather, refined – Refined aniline leather== | ==Aniline leather, refined – Refined aniline leather== | ||

| − | At the beginning of 2016, the term "aniline leather, refined" appeared for the first time in the new formulation of RAL 430/4. | + | At the beginning of 2016, the term "aniline leather, refined" appeared for the first time in the new formulation of RAL 430/4. The definition stated that a refined aniline leather must have almost completely visible [[Leather hair pores - Hair follicles|hair pore]]. An applied pigment coating is not allowed to exceed 0.015 mm. In the case of aniline leather, a pigment-free coating should not be above 0.01 mm. |

In RAL 061 A1 (March 2016) the rules were tightened once more. Accordingly, the [[finish|pigmentation]] is not allowed to exceed 0.01 mm. The natural hair pores must remain clearly visible and the hair pore channels are not allowed to be completely filled. | In RAL 061 A1 (March 2016) the rules were tightened once more. Accordingly, the [[finish|pigmentation]] is not allowed to exceed 0.01 mm. The natural hair pores must remain clearly visible and the hair pore channels are not allowed to be completely filled. | ||

Revision as of 09:54, 24 January 2017

Contents

The gap between aniline leather and semi aniline leather

The lack of a defining standard between pure aniline leather and semi-aniline leather has led to a certain amount of confusion. Pure aniline leather must not have a pigmented surface of any kind, not even a minimal one, according to the definition of this type of leather. Therefore, aniline leather is susceptible to stains. As soon as any pigmentation is applied, it is no longer classed as aniline leather. If the leather is only minimally pigmented so that it remains as natural as possible, the leather does not meet the minimum requirements for the leather type semi-aniline leather either.

Aniline leather is not allowed to have a pigment coating.

This conflict occurs mostly in upholstery leathers. Understandably, the leather furniture manufacturers want the best leather quality (aniline leather). But, at the same time, they want the aniline leather not to fade, not to have natural markings on leather and as few colour deviations as possible and not be susceptible to stains.

In aniline leather liquid penetrates immediately. A light finish improves protection.

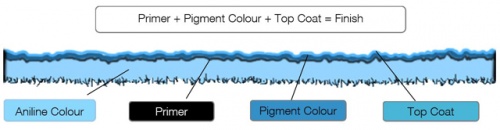

To solve this dilemma, some tanneries have applied thin layers of pigment onto the leather. This was intended to be as close as possible to aniline leather, while applying a light protection in order to meet the legitimate wishes of the furniture trade and the end users. If, during investigations, pigments were found on the surface the tannery would be accused of failing to sell high quality aniline leather. Then, if it was tested for semi aniline leather, it failed to meet the minimum requirements for light fastness or friction resistance.

This regulatory gap gave the impression that the tannery had produced a deficient leather. But a leather that falls between aniline leather and semi aniline leather is actually of excellent quality. It is coated as little as possible to preserve the naturalness. Although this offers minimum protection, it ensures that this type of leather will not fade so easily and be less stain sensitive than completely porous aniline leather.

It's of little advantage to the consumer that pure aniline leather, which falls within the highest price bracket, fades over time and that normal stains are difficult to remove. Thus, slightly pigmented leather between aniline and semi-aniline is a much better option for leather manufacturers, leather traders, furniture manufacturers and the end customers.

Aniline leather, refined – Refined aniline leather

At the beginning of 2016, the term "aniline leather, refined" appeared for the first time in the new formulation of RAL 430/4. The definition stated that a refined aniline leather must have almost completely visible hair pore. An applied pigment coating is not allowed to exceed 0.015 mm. In the case of aniline leather, a pigment-free coating should not be above 0.01 mm.

In RAL 061 A1 (March 2016) the rules were tightened once more. Accordingly, the pigmentation is not allowed to exceed 0.01 mm. The natural hair pores must remain clearly visible and the hair pore channels are not allowed to be completely filled.

Presumably the "aniline leather is refined" will overtake the pure aniline leather in the furniture sector. The tendency to the patina formation of the high-price pure aniline leather only makes sense for buyers who want exactly this property.

Although the distinctiveness of the types of leather does not get easier for consumers and experts by this new kind of leather, the manufacturers should adhere to the new definitions in the declarations of the leather. This solution is the right way to offer the end users the best smooth leather in the high price segment. It will certainly take a few years until the new term "aniline leather refined" has become established.

The following examples of pore recognisability are only indicative. Depending on the leather batch and area of the skin, large fluctuations of the pore visibility can already be present within one skin.

Pure aniline leather: The pores are completely recognisable and no finish is applied on the leather surface.

Refined aniline leather has only a very thin pigment coating on the surface, which is hardly noticeable.

Semi-aniline leather: Pores are still clearly visible, but a thin layer of paint is on the leather surface which is more then on aniline leather, refined.

Pigmented smooth leather: Pores

are no longer recognisable because a thick layer of paint is filling and covering the pores.

Video about different types of leather

Video about different kinds of smooth leather.

Additional information

- Aniline leather

- Porous leather

- What should be considered when buying new leather furniture?

- Finish - Pigmented leather

- Smooth leather

- Leather hair pores

a kotori web solution

a kotori web solution