Difference between revisions of "Leather edge finish"

m |

|||

| Line 8: | Line 8: | ||

In bulk production, the edge protection is applied by machine. The leather is then passed through machines which transfer the ink to the cutting edge via colour-soaked rollers. | In bulk production, the edge protection is applied by machine. The leather is then passed through machines which transfer the ink to the cutting edge via colour-soaked rollers. | ||

| − | It is also possible to apply edge protection manually | + | It is also possible to apply edge protection manually but the work needs to be done very precisely to get an even result. The application is done with brushes or sponges. The variance of the covering ranges from a light colouration to a strong coating. |

Revision as of 23:25, 13 December 2016

Leather edge finish is applied to the cutting edges of leather for protection or for fashion reasons. The fibre structure of leather is clearly visible in cutting edges. This open fibre structure can soil easily and moisture can penetrate.

In bulk production, the edge protection is applied by machine. The leather is then passed through machines which transfer the ink to the cutting edge via colour-soaked rollers.

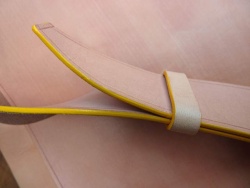

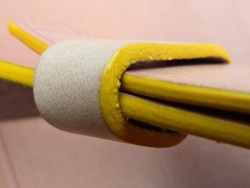

It is also possible to apply edge protection manually but the work needs to be done very precisely to get an even result. The application is done with brushes or sponges. The variance of the covering ranges from a light colouration to a strong coating.

Light edge colouring on a Louis Vuitton bag.

Stronger edge finish on a BREE bag.

Cutting edge without coating. - Rubber coated cutting edge with strong coating by machine.

Manual application of leather edge finish with a sponge.

Additional information

Where to buy leather edge finish?

![]() -> GB, USA, Ireland: www.colourlock.com

-> GB, USA, Ireland: www.colourlock.com

![]() -> In German: www.lederzentrum.de

-> In German: www.lederzentrum.de

![]() -> Rest of the world: partners worldwide

-> Rest of the world: partners worldwide

a kotori web solution

a kotori web solution