Difference between revisions of "Leather shoes"

| Line 34: | Line 34: | ||

In the production of upper leather for shoes nowadays all types of leather are processed. Often the distinction of leathers is not easy. The most common tyes of leather are [[Pigmented leather|pigmented smooth leather]] (pigment binder coating on the [[grain side]]), [[Aniline leather|aniline leather]] ([[Open pore leather|open pore]] grain side leather), [[Pull up leather - Greased leather - Waxed leather - Oiled leather|waxed or oiled leather]], [[Suede|suede]] and [[Nubuck|nubuck]]. For sole leather, [[Vegetable-tanned leather|vegetable tanned]] [[Cow leather|cow hide]] is processed. The processed footwear materials must be [[Genuine leather|specified]] in Europe. | In the production of upper leather for shoes nowadays all types of leather are processed. Often the distinction of leathers is not easy. The most common tyes of leather are [[Pigmented leather|pigmented smooth leather]] (pigment binder coating on the [[grain side]]), [[Aniline leather|aniline leather]] ([[Open pore leather|open pore]] grain side leather), [[Pull up leather - Greased leather - Waxed leather - Oiled leather|waxed or oiled leather]], [[Suede|suede]] and [[Nubuck|nubuck]]. For sole leather, [[Vegetable-tanned leather|vegetable tanned]] [[Cow leather|cow hide]] is processed. The processed footwear materials must be [[Genuine leather|specified]] in Europe. | ||

| − | The [[Leather industry#Footwear industry|shoe industry]] is the world's largest processor of leathers. Worldwide annual 14 billion pairs of leather shoes are produced. 11.5 billion come from Asian factories and China is with 8 billion pairs the biggest producer. By comparison, in Germany only 26 million pairs of shoes are produced per year. | + | The [[Leather industry#Footwear industry|shoe industry]] is the world's largest processor of leathers. Worldwide annual 14 billion pairs of leather shoes are produced. 11.5 billion come from Asian factories and China is with 8 billion pairs the biggest producer. By comparison, in Germany only 26 million pairs of shoes are produced per year. Roughly 5 million pairs of shoes are made in the UK (discounting the two main producers ‘New Balance’ & ‘Hotter’ ([http://britishfootwearassociation.co.uk/promotion/made-in-britain/ britishfootwearassociation.co.uk]). |

The most intense consumption of shoes takes place in the USA. According to the statistics, every American buys six pairs of shoes every year. In Europe, Japan and Canada, between three and five pairs of shoes are bought per year. The average Chinese buys 2.5 pairs of shoes per year. | The most intense consumption of shoes takes place in the USA. According to the statistics, every American buys six pairs of shoes every year. In Europe, Japan and Canada, between three and five pairs of shoes are bought per year. The average Chinese buys 2.5 pairs of shoes per year. | ||

| Line 147: | Line 147: | ||

'''Important''' | '''Important''' | ||

| − | * Leather shoes are available in all imaginable types of leather. Some of these many types of leather are very sensitive and not easy to maintain. These include the [[Suede|suede]], [[Nubuck|nubuck]] or [[Aniline leather|aniline leather]]. These open pore leathers are always sensitive! No matter how much the seller promotes a [[Waterproofing leather|waterproofing]]. Always make a water rubbing test. A drop of water would sink into open pore leather and darken it. Penetrates the water, the shoe or boot is never suitable for wet weather! Not even with an [[Waterproofing leather| | + | * Leather shoes are available in all imaginable types of leather. Some of these many types of leather are very sensitive and not easy to maintain. These include the [[Suede|suede]], [[Nubuck|nubuck]] or [[Aniline leather|aniline leather]]. These open pore leathers are always sensitive! No matter how much the seller promotes a [[Waterproofing leather|waterproofing]]. Always make a water rubbing test. A drop of water would sink into open pore leather and darken it. Penetrates the water, the shoe or boot is never suitable for wet weather! Not even with an [[Waterproofing leather|waterproof treatment]]! No care products makes this leather insensitive. Otherwise it would have been made by the manufacturer. |

* Bright leather is more sensitive than dark leather. Stains and scratches on bright shoes are much more visible and can be less easily removed with care and [[Leather cleaner|cleaning products]]. If a bright leather is also open pore, then its not long lasting or just for special occasions. | * Bright leather is more sensitive than dark leather. Stains and scratches on bright shoes are much more visible and can be less easily removed with care and [[Leather cleaner|cleaning products]]. If a bright leather is also open pore, then its not long lasting or just for special occasions. | ||

* Leather shoes can [[Dye transfer from leather|discolour]] inside. Make a rub test with a bright cloth. This way you check, what will happen to light socks. | * Leather shoes can [[Dye transfer from leather|discolour]] inside. Make a rub test with a bright cloth. This way you check, what will happen to light socks. | ||

| Line 159: | Line 159: | ||

</p> | </p> | ||

<p align=center> | <p align=center> | ||

| − | ''With so [[Open pore leather| | + | ''With so [[Open pore leather|porous]] bright [[Aniline leather|aniline leathers]] also an intense [[Waterproofing leather|waterproof]] is not sufficient protection. This is a fair-weather footwear.''<br></p> |

<p> </p> | <p> </p> | ||

Revision as of 16:24, 23 October 2016

Contents

History

The oldest depiction of footwear comes from the cave of Altamira in Spain and is approximately 15,000 years old. There are pictures of hunters with a kind of boots.

The oldest footwear found is 8300 years old. It were sandals and they were found in the Arnold Research Cave in Missouri, USA. They have been made from plant material.

The oldest known leather shoe was excavated in an Armenian cave by archaeologists. The estimated age of 5,500 years (period between Neolithic and Bronze Age). The shoe is made from one piece of cowhide and has a lining of grass.

The famous footwear from the glacier mummy Ötzi is about 5,300 years old. This shoe structure was surprisingly complex. The upper (outer shoe) was made of deerskin with hair side facing out as protection against moisture. The sole was made of better insulating bearskin with hair side facing inside.

1st Photo:Roman legionary sandal 1st century AD (DLM - German Leather Museum in Offenbach)

2nd Photo:Cow's Mouth shoe 16th century (DLM - German Leather Museum in Offenbach)

Why leather?

Shoes are available from many different materials and in infinite colours and shapes. First, the shape and appearance of a shoe is to protect the foot against injuries and the climate. The appearance of a shoe is also influenced by fashion or displays the status of the wearer. There are women's shoes and men's shoes, slippers, sneakers, boots, hiking boots, sandals and much more.

Since there are shoes, leather is processed, because this resource is in sufficiently available. Leather can be formed, it can be sewed, it can be waterproofed without losing the breathability and provides a strong protection against injuries of the feet because of its robustness. You do not sweat as much in leather shoes as with substitution materials. Fabric is also breathable, but waterproofing is not as good as on leather and also the protection against injuries is significantly worse. Through these outstanding properties leather is still the best material for shoes. Most substitution material is processed for price reasons.

Materials and Figures

In the production of upper leather for shoes nowadays all types of leather are processed. Often the distinction of leathers is not easy. The most common tyes of leather are pigmented smooth leather (pigment binder coating on the grain side), aniline leather (open pore grain side leather), waxed or oiled leather, suede and nubuck. For sole leather, vegetable tanned cow hide is processed. The processed footwear materials must be specified in Europe.

The shoe industry is the world's largest processor of leathers. Worldwide annual 14 billion pairs of leather shoes are produced. 11.5 billion come from Asian factories and China is with 8 billion pairs the biggest producer. By comparison, in Germany only 26 million pairs of shoes are produced per year. Roughly 5 million pairs of shoes are made in the UK (discounting the two main producers ‘New Balance’ & ‘Hotter’ (britishfootwearassociation.co.uk).

The most intense consumption of shoes takes place in the USA. According to the statistics, every American buys six pairs of shoes every year. In Europe, Japan and Canada, between three and five pairs of shoes are bought per year. The average Chinese buys 2.5 pairs of shoes per year.

In Germany, every women has 17.3 pairs of shoes at home and men have 8.2 pairs (according to a survey of 2014).

Expensive brand shoes - shoes in the shoe shop - shoes on the cheap market

The labelling requirement for shoes

In Europe there is a material labelling requirement for shoes. Manufacturer of footwear (sandals, shoes, boots) are obliged to provide the processed materials. In text form or as thumbnails.

The following components of a shoe must be identified in terms of the used material:

Image 1: Uppers: The upper outer material is meant.

Image 2: Lining and insole: The upper and lower materials inside the shoe are meant.

Image 3: Sole: The outsole is the contact material to the floor which wears off.

The specified material must be 80% of the complete volume and surface of the processed materials. If several materials are processed (e.g. leather and textile as upper material), the main materials must be specified.

The following materials are distinguished:

Image 1: Leather: "Leather" are hides and skins were its original fibre structure was not changed. Materials which are produced from dissolved or crushed leather fibres and processed into sheets are not "leather". An applied colour film or layer is not allowed to be thicker than 0.15 mm.

Image 2: Coated leather: Coated leather is leather, where a painting or a film is thicker than 0.15 mm, but not more than 1/3 of the total thickness. If the coating greater than 1/3, then it is no more leather but a synthetic leather.

Image 3: Textile: Textiles are all natural and synthetic textiles.

Image 4: Other Material: Other materials are all materials that are not covered by the upper groups. For example, rubber or plastic for an outsole.

Leather quality of shoes

There are many criteria that define the quality of a shoe.

- rub fastness (the resistance of the leather surface to mechanical abrasion)

- water vapor permeability

- tear resistance (the force that must be applied to increase existing tears)

- discolouration (the staining of socks caused by the leather lining inside the shoe)

- adhesion of the leather colour

- bending behavior

- light fastness (resistance of the material's colour to fading)

Main leather terms for shoes

Upper Leather

The upper leather is leather on the visible side of the shoe. It makes up the largest part of the processed leather for shoes. The variety of processed leathers is unlimited, and leather many species are processed. Typical is cow leather, calfskin, goatskin, sheep leather and even horse leather in the high price segment. But also all exotic leathers are processed. Crocodile leather, snake leather and a lot of other exotic leathers are processed. Dependend on the fashion, the processed leather can be coarse or fine-grained, matt or glossy, metallic or luminous. Most upper leather is Chrome tanned.

Upper leather in many variations: coloured - perforated - carved.

Sole leather

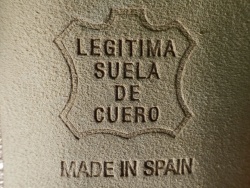

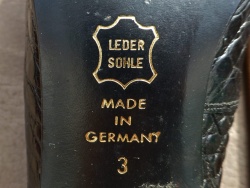

When the sole of a shoe is processed of leather, it's called leather sole. Sole leather is thick (2.5 - 6 mm) little pliable and solid vegetable-tanned leather.

Leather sole, made in Spain with a sensitive lightly sanded leather.

Leather sole made in Germany from cow with crocodile upper leather.

Not really easy to care: Golf shoes with white suede as sole and rubber studs.

Leather lining

Shoes can have a leather lining inside. It's not the leather where the foot is on, but the leather, which is in contact to the rest of the foot in the shoe. A leather lining, therefore needs to feel good and be permeable to water vapour, so you do not sweat. As leather lining, leather from cow, calf, goat, sheep and pig is processed.

Shoe Care - Leather selection

There is a wide range of leather care product for shoes. In the shoe stores often matching shoe care products are offered. But there is an endless selection of leather types in footwear. From easy to care pigmented smooth leather to pull up leather to highly sensitive aniline leather or suede and nubuck. Often, the clients are not aware of the sensitivity of some types of leather and overestimate the possibilities of waterproofing.

Important

- Leather shoes are available in all imaginable types of leather. Some of these many types of leather are very sensitive and not easy to maintain. These include the suede, nubuck or aniline leather. These open pore leathers are always sensitive! No matter how much the seller promotes a waterproofing. Always make a water rubbing test. A drop of water would sink into open pore leather and darken it. Penetrates the water, the shoe or boot is never suitable for wet weather! Not even with an waterproof treatment! No care products makes this leather insensitive. Otherwise it would have been made by the manufacturer.

- Bright leather is more sensitive than dark leather. Stains and scratches on bright shoes are much more visible and can be less easily removed with care and cleaning products. If a bright leather is also open pore, then its not long lasting or just for special occasions.

- Leather shoes can discolour inside. Make a rub test with a bright cloth. This way you check, what will happen to light socks.

- Products are offered towiden tight shoes. Buy only shoes that really fit. The scope for vastness of the leather is very low.

With so porous bright aniline leathers also an intense waterproof is not sufficient protection. This is a fair-weather footwear.

Video about shoe care

Cleaning and care of aniline and porous leather shoes.

Cleaning and care of suede and nubuck shoes.

Additional information

- Basic rules when dealing with leather shoes

- Leather care

- Waterproofing

- Dye transfer from leather

- Leather boots

Bespoke shoes

Shoes are also manufactured in Europe. Artworks are created by custom made shoe manufacturers, which sometimes process exotic leathers.

A beautiful video about the production process of leather shoes.

Shoes made of ostrich leather and blue golf shoes made by Himer bespoke shoes

Bespoke shoes made of stingray leather made by Himer bespoke shoes

Ironed salmon leather shoes and ostrich leather shoes made by Jacob, F. Shoes

Stingray leather and cordovan shoes made by Jacob, F. Shoes

Eel leather and Alligator leather shoes made by Jacob, F. Shoes

Historic shoes

Shoes have had a wide variety of colours and shapes over the centuries and cultures.

Women's shoe made of gold leather - Roman legionary sandal 1st cent. AD (DLM - German Leather Museum in Offenbach)

Shoe from the time around 1540 - Pointed shoe (DLM - German Leather Museum in Offenbach)

Shoe Chopine from Venice from the time around 1600 - Lady's shoe (height of fashion reasons) (DLM - German Leather Museum in Offenbach)

Picture gallery

Trainers made of suede - cow hide shoes - Pull up leather shoes

Shoes made of salmon leather (www.ledermanufaktur.com) - painted shoes - sheepskin slippers

Beautiful painted shoes made by www.schunikat.com.

Leather boots custom made for 2.500 €, size 47, 15 cm heel made by (www.ledermanufaktur.com).

Snakeskin - stretch leather - Eel leather

"Used-Look" - Embossed Shoe

Shoe made of suede - Leather ice-skates

Shoes of a minister of the green party in sneakers at the swearing in as Environment Ministers in Germany. - Toe shoe (DLM - German Leather Museum in Offenbach).

Leather boots made of snakeskin. - Printed lady's shoe from Spain.

Reproduction of jugglers shoes from the middle ages Jacob, F. Shoes and www.ledermanufaktur.com

Metallic leather and patent leather.

Women's shoes made of crocodile leather.

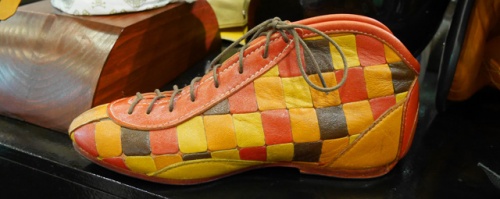

Patchwork shoes

Leather sandals made by Selestudio

Patent leather shoes

Additional information

a kotori web solution

a kotori web solution