Difference between revisions of "Vegetable-tanned leather"

| (3 intermediate revisions by one user not shown) | |||

| Line 9: | Line 9: | ||

| − | == | + | ==What is vegetable tanned leather?== |

Vegetable tanning refers to leather that is [[tanning leather|tanned]] with oak bark, spruce bark, [[quebracho]], [[tara|tara pods]], [[Olive leather|olive leaves]], [[Rhubarb leather|rhubarb roots]], [[mimosa]] or coffee bean shells in the pit or in the [[Tanning leather#Tanning drum|tanning drum]]. The [[Tannins|tanning agent]] is then a vegetable tanning agent. Also the term "[[natural leather]]" is used. | Vegetable tanning refers to leather that is [[tanning leather|tanned]] with oak bark, spruce bark, [[quebracho]], [[tara|tara pods]], [[Olive leather|olive leaves]], [[Rhubarb leather|rhubarb roots]], [[mimosa]] or coffee bean shells in the pit or in the [[Tanning leather#Tanning drum|tanning drum]]. The [[Tannins|tanning agent]] is then a vegetable tanning agent. Also the term "[[natural leather]]" is used. | ||

| − | Tanning with plant substances has existed for over 5,000 years and was, for many centuries, the main [[tanning leather|tanning method]]. Ornaments placed on stone coffins reveal that vegetable tanning was around in the 4th millennium BC in Egypt. Since the discovery of Ötzi in the ice of the Alps it is evident that several leather types were prepared for various uses even 5,000 years ago. Recently, the more modern and [[leather industry|industrialised tanning]] methods have become common and it can be assumed that nowadays only 10 - 12% of all leather is vegetable-tanned. The cost and [[leather quality|quality]] advantages of [[Chrome tanned|chrome-tanned]] leather have reduced the proportion of vegetable-tanned leather to a niche. Before chrome tanning, [[tanning]] with vegetable tanning agents was the dominant tanning method. In the niche where vegetable tanned leather is superior to other [[tanning|tanning methods]], or where leather lovers prefer this natural [[tannins|tanning agent]], vegetable tanned leather is strong and will continue to have its place. | + | Tanning with plant substances has existed for over 5,000 years and was, for many centuries, the main [[tanning leather|tanning method]]. Ornaments placed on stone coffins reveal that vegetable tanning was around in the 4th millennium BC in Egypt. Since the discovery of Ötzi in the ice of the Alps it is evident that several leather types were prepared for various uses even 5,000 years ago. There is no exact account of where exactly vegetable tanning originated, as it was developed independently in different cultures. Various ancient civilizations such as the Egyptians, Greeks, Romans and Indians are believed to have developed vegetable tanning techniques. |

| + | |||

| + | Recently, the more modern and [[leather industry|industrialised tanning]] methods have become common and it can be assumed that nowadays only 10 - 12% of all leather is vegetable-tanned. The cost and [[leather quality|quality]] advantages of [[Chrome tanned|chrome-tanned]] leather have reduced the proportion of vegetable-tanned leather to a niche. Before chrome tanning, [[tanning]] with vegetable tanning agents was the dominant tanning method. In the niche where vegetable tanned leather is superior to other [[tanning|tanning methods]], or where leather lovers prefer this natural [[tannins|tanning agent]], vegetable tanned leather is strong and will continue to have its place. | ||

| Line 79: | Line 81: | ||

The tanning agent is placed together with the hides in water-filled pits, resulting in a bath containing tannic acid after a few days. The skin is regularly exposed to additional baths with higher tannin concentrations. | The tanning agent is placed together with the hides in water-filled pits, resulting in a bath containing tannic acid after a few days. The skin is regularly exposed to additional baths with higher tannin concentrations. | ||

| + | |||

| + | A special type of pit tanning is the traditional pit tanning. The traditional pit tanning is carried out in particular for [[Leather shoes#Main leather terms for shoes|sole leather]] (particularly [[Thickness of leather|thick]] and [[Haptic evaluation of leather surfaces#Strength of the leather|firm]] leather), which takes 9 to 18 months. Modern vegetable tanning processes reduce this time to just a few weeks. In combination with tanning in [[Tanning drum]], the process can even be reduced to 4-10 days, whereby the leather does not have exactly the same properties as with pure pit tanning, which produces particularly [[Haptic evaluation of leather surfaces#Strength of the leather|firm]] leather with a high [[Tannins|tanning agent]] content. Apart from [[Leather shoes#Main leather terms for shoes|sole leather]], these leathers are also often used for [[Carving leather|carving]], [[Embossed leather|embossing]], [[Leather belt|straps]] and other specialties because the leather has the [[leather quality|best properties]] for this use. | ||

Latest revision as of 07:27, 4 July 2023

Contents

What is vegetable tanned leather?

Vegetable tanning refers to leather that is tanned with oak bark, spruce bark, quebracho, tara pods, olive leaves, rhubarb roots, mimosa or coffee bean shells in the pit or in the tanning drum. The tanning agent is then a vegetable tanning agent. Also the term "natural leather" is used.

Tanning with plant substances has existed for over 5,000 years and was, for many centuries, the main tanning method. Ornaments placed on stone coffins reveal that vegetable tanning was around in the 4th millennium BC in Egypt. Since the discovery of Ötzi in the ice of the Alps it is evident that several leather types were prepared for various uses even 5,000 years ago. There is no exact account of where exactly vegetable tanning originated, as it was developed independently in different cultures. Various ancient civilizations such as the Egyptians, Greeks, Romans and Indians are believed to have developed vegetable tanning techniques.

Recently, the more modern and industrialised tanning methods have become common and it can be assumed that nowadays only 10 - 12% of all leather is vegetable-tanned. The cost and quality advantages of chrome-tanned leather have reduced the proportion of vegetable-tanned leather to a niche. Before chrome tanning, tanning with vegetable tanning agents was the dominant tanning method. In the niche where vegetable tanned leather is superior to other tanning methods, or where leather lovers prefer this natural tanning agent, vegetable tanned leather is strong and will continue to have its place.

A campaign by the Italian leather industry for vegetable tanned leather (www.pellealvegetale.it).

Vegetable-tanned leather is usually recognized by the brown colouration. Since plant tanning dominated long before chrome tanning, in particular old leather is mostly vegetable-tanned. Today only thick and firm leather is vegetable-tanned. For high-quality shoes, e.g. for the leather soles. Due to their excellent shape retention, vegetable-tanned leather can be moulded, carved and embossed very well. Leather can consist of up to 45% tanning agents. In particular, vegetable tanning agents are better absorbed by leather and therefore fill it better, are therefore heavier and can be better processed into firm leather.

Vegetable tanning is based on tannins (polyphenols and gallic acid) which are found naturally in plant species. Plants store these as a defence mechanism to ward off attacks from potential predators whose digestion is adversely affected upon consumption. Tannins are found in varying concentrations in different plants. In addition to the plants mentioned above, tannins are also contained in wine, chestnuts, hops, sumac and black and green tea. In food, tannins are perceived as dry, rough and furry. The taste of red wine is fundamentally influenced by the type of tannins and their concentration. Many plants used for leather tanning require up to 30 years growth, to allow sufficient amounts of tannins to be produced. Other plants contain more tannins when they are younger. There are around 300 different plant species worldwide, which can be used for tanning.

- Oak is suitable for all leather. Oak and spruce bark from younger trees are used, because they contain more tannin.

- Chestnut gives a hard and reddish leather.

- Mimosa bark and Acacia make leather rather pliable and supple.

- Valonea is a Mediterranean, wild species of oak, which grows mainly in Turkey and in Greece. Dried Valonea acorn cups (also called Trillo) have a high tannin content, between 32% and 45%. Valonea is used to make soft and tough leather. Valonea-tanned leather has higher colour-fastness ratings in comparison to other vegetable-tanned leather.

- Bark from the flat topped yate or swamp yate (eucalyptus occidentalis) has an extremely high tannin content of 46 - 49%. The tree grows in West Australia and is up to 25 meters high. Since the plant is now rare, the tannin is hardly used.

Vegetable tannins - Quebracho wood

In Middle Ages Europe, forests were cultivated with tannin-rich oak varieties. The tannin-containing bark of the trees was peeled off and brought to mills. These mills were mostly located close to tanneries.

Tannins

Not every plant contains the same percentage of tannin. Tannin is mainly a substance that is released during stressful reactions of the plant (e.g. parasite attack).

Within the same plant, the tannin content varies:

- Oak bark contains about 10% tannins (in older trees about 5%) and oak apples up to 70%. The resulting leather is light brown.

- Spruce bark has 15% tannins. However, in spruce wood it is a maximum of 1%. Also, this leather is light brown.

- Chestnuts can reach 10 percent tannins in wood of old trees. The leather is medium brown and chewy.

- Willow bark has 10% tannin and delivers yellowish leather.

- The bark of old birch contains 10% tannins. The resulting leather is also yellowish and soft, but resistant.

- Valonea has a very high tannin level with 32%. The leather is tough and solid.

- Galls or cecidia contains 55–65 % tannic acid. There are over-growths on plants through the eggs of insects. Around the larvae, tannin-containing growths develop. The countries of origin are Hungary, Yugoslavia and Austria.

The dry substance of the vegetable tanning agent extracts delivered to the tannery consists of around 75% tannins, which are absorbed and bound by the hide to be tanned, and 25% non-tanning agents. Over 90% of the tanning agents contained in the tanning agent extract are absorbed by the leather during the tanning process.

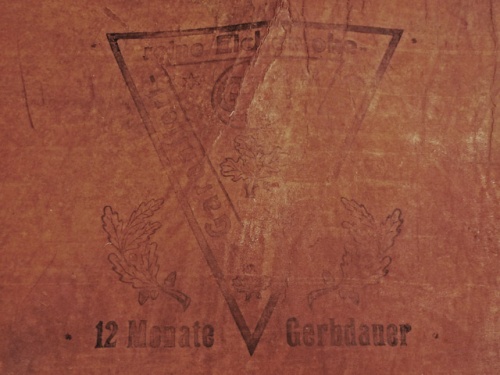

Leather tanned with oak with stamp: "pure oak wood - 12 months tanning period".

The tanning process

The vegetable tanning process takes about 20-30 months. Per Skin about 30 kg of bark or 20 kg of fruit or 90 kg oak wood is needed. In 2009, world demand for vegetable tanning raw material was about 130,000 tonnes. The modern tanning with vegetable tanning agents only takes 59 hours compared to a comparable chrome tanning with 54 hours.

The tanning agent is placed together with the hides in water-filled pits, resulting in a bath containing tannic acid after a few days. The skin is regularly exposed to additional baths with higher tannin concentrations.

A special type of pit tanning is the traditional pit tanning. The traditional pit tanning is carried out in particular for sole leather (particularly thick and firm leather), which takes 9 to 18 months. Modern vegetable tanning processes reduce this time to just a few weeks. In combination with tanning in Tanning drum, the process can even be reduced to 4-10 days, whereby the leather does not have exactly the same properties as with pure pit tanning, which produces particularly firm leather with a high tanning agent content. Apart from sole leather, these leathers are also often used for carving, embossing, straps and other specialties because the leather has the best properties for this use.

During tanning, the leather hangs in pits that are filled with the tanning liquor.

Videos about vegetable tanning

Vegetable tanning with oak tannins.

Vegetable tanning in Tuscany, Italy.

Labelling of Leather

Besides the term "vegetable-tanned leather", terms like "natural leather" or "bio leather" are in use, since the tannins are derived from natural raw materials.

Some people react to chromium VI, which is rarely found in leather. Therefore, some people look for chrome-free leather or pure vegetable tanned leather to avoid possible allergies. As tanning methods can be mixed in the leather production, it is important to ask for chrome-free leather (FOC = Free of Chrome) to be sure. The term "vegetable-tanned leather" doesn`t assure this alone. In Europe leather may only be labelled as vegetable tanned without additional information if the total content of the tanning metals (Cr, Al, Ti, Zr, Fe) does not pass 0.3% of the dry weight. If the proportion is higher, the goods must be declared corresponding.

Old vegetable-tanned leather.

The light fastness of vegetable-tanned leather

The dyes in aniline leather or the pigments on finished leather become lighter by light (fading). In the case of uncoloured vegetable-tanned leathers, it behaves differently. The leather darkens by light, moisture and fat.

Vegetable-tanned leather, which was never moistened or oiled or greased, will become darker first, but will become brighter later as a result of drying. Probably this effect is related to fats and oils in the leather. At first, grease moves up to the top of the leather and darkens, but the dryness makes it brighter with time because the fats slowly dry out. But as soon as water or grease gets onto the leather, it darkens strongly.

Vegetable tanned leather day 0, day 16 and day 50 in sunlight.

| Tanning methods |

|---|

| Chrome tanning - Vegetable tanning - Synthetic tanning - Tanning with fats and oils |

Additional information

- Leather production

- Chrome-free leather - FOC = Free of Chrome

- Bio leather

- Natural leather

- Leather production

- Leather chemistry

- Tannins

- Chrome tanning

- Synthetic tanning

- Tanning with fats and oils

- Tawing with alum

- Brain tanning

Vegetable tannins

a kotori web solution

a kotori web solution